Cooling and Humidification

At Forever Flowering we approach cooling in two stages:

First Stage

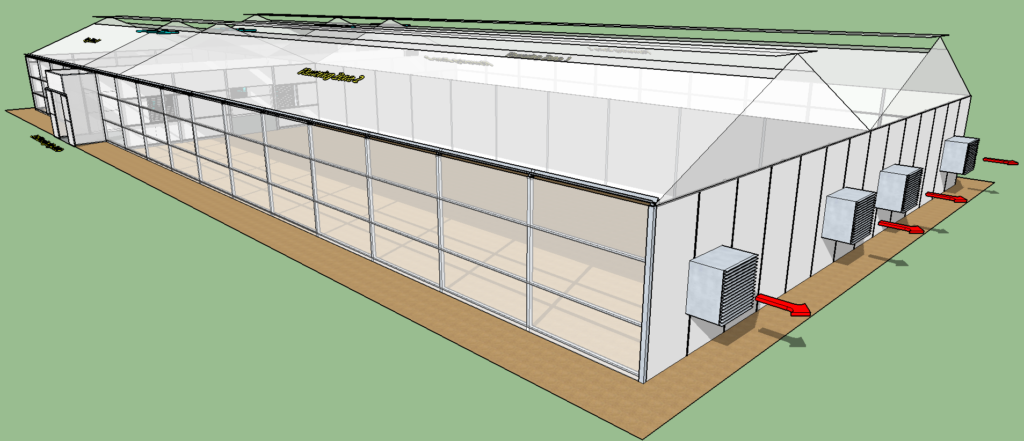

There is no fan on earth that can move as much air as the convection process can. A properly designed greenhouse by FFG creates a low impact, natural transmission of air. This passive cooling system is achieved by integrating our ridge and side vents, allowing moist and hot air to passively escape the structure. Because your fans are not always running, this simple, but state-of-the-art method saves you money on operating costs and extends the lifespan of your equipment.

Second Stage

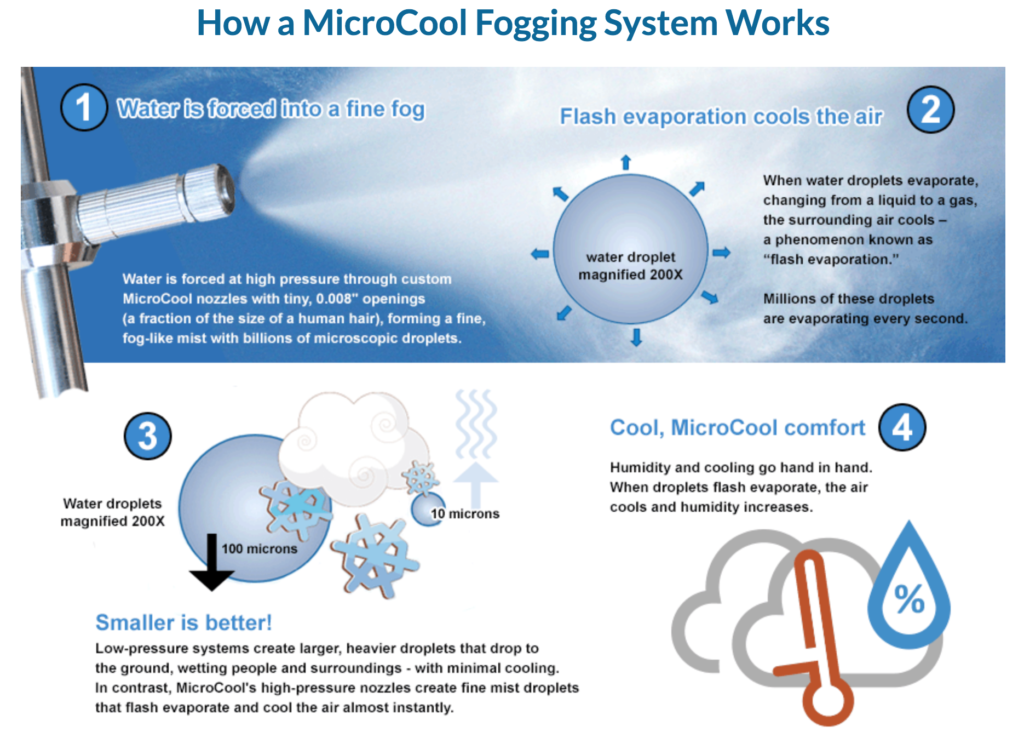

Since Forever Flowering began business in 2006, we have been designing our greenhouses with high pressure fogging systems to both cool and, if necessary, add humidity in very dry areas. Fogging systems are designed to cool your structure efficiently and consistently. Through years of practical, personal research and development, we’ve found that fogging systems outperform wet walls in several areas.

FOGGING VS. WET WALLS

High-pressure fogging and mechanical ventilation systems are designed to cool your structure efficiently and consistently. Fogging systems have been found to outperform wet walls in several areas, including consistency, efficiency, and the general health of the plants.

Consistency:

Fogging systems have small pipes with emitters that are mounted throughout the greenhouse. These can be adjusted as needed to control the quantity of moisture being dispersed throughout the greenhouse. This creates a consistent environment in your greenhouse, regardless of the climate your plants are growing in.

Wet Walls are created by dispersing fresh and recirculated water onto pads placed on the air intake walls of your greenhouse. As air enters through the wet wall, it moistens and cools. When this cool, moist air travels across your greenhouse, it begins to warm and dry as it moves further from its entry point, decreasing the environmental consistency needed to grow top shelf flowers

Wet Walls are created by dispersing fresh and recirculated water onto pads placed on the air intake walls of your greenhouse. As air enters through the wet wall, it moistens and cools. When this cool, moist air travels across your greenhouse, it begins to warm and dry as it moves further from its entry point, decreasing the environmental consistency needed to grow top shelf flowers

Efficiency:

When a wet wall’s environmental controller is activated, the pad vent first begins to pump water, when sufficiently wet, the cooling system then begins to blow air across the cool, wet pad and ultimately, over the entire crop, before leaving the building through mechanical ventilation.

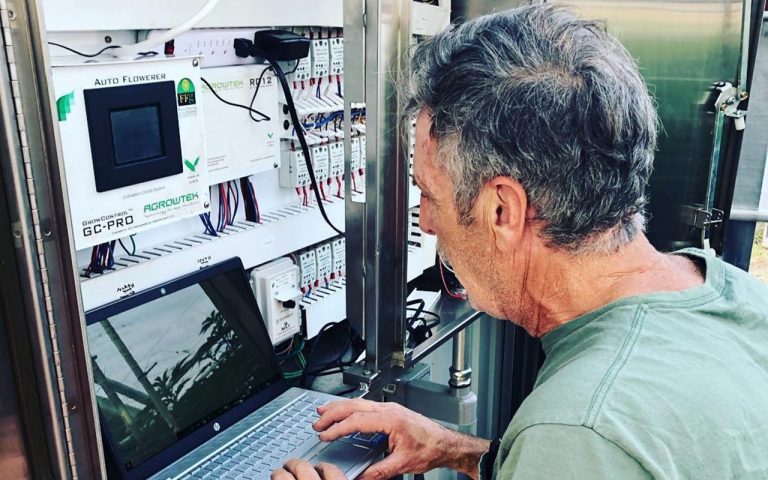

Forever Flowering is committed to creating efficient and sustainable greenhouse solutions with the lowest carbon footprint. To this end, our fogging systems are connected to fully charged, low pressure piping that allows the fog to be dispersed immediately upon being triggered. This reduces the transition time between cooling and ventilation cycles.

Forever Flowering is committed to creating efficient and sustainable greenhouse solutions with the lowest carbon footprint. To this end, our fogging systems are connected to fully charged, low pressure piping that allows the fog to be dispersed immediately upon being triggered. This reduces the transition time between cooling and ventilation cycles.

A Case Study:

We had a client who was operating approximately 40,000 sq. ft of canopy while running his wet wall 24/7 in order to keep his greenhouse environment hospitable for his flowering plants.

In an attempt to determine how much water he was consuming per day, he installed a water flow meter on the inlet of his pad vent system. He measured just under 40,000 gallons of water being used each day in his wet wall cooling system.

That equates to one gallon of water per square foot of canopy to cool his greenhouse. We determined that, considering his environmental location, using a fogging system would enable the farmer to decrease his water usage by approx. 25% per day. From 40,000 gallons per day to 29,000 gallons per day.

In an attempt to determine how much water he was consuming per day, he installed a water flow meter on the inlet of his pad vent system. He measured just under 40,000 gallons of water being used each day in his wet wall cooling system.

That equates to one gallon of water per square foot of canopy to cool his greenhouse. We determined that, considering his environmental location, using a fogging system would enable the farmer to decrease his water usage by approx. 25% per day. From 40,000 gallons per day to 29,000 gallons per day.

Health Of Your Plants:

When growing in soil, or in soil-type conditions, the soil will stay moisture-laden the closer it is to where the cool, moist air of a wet wall enters the greenhouse. If the whole crop is watered at the same time, the plants’ whose soil is located closest to the exhaust side, where it’s hotter and drier, will dry out much faster than the soil of the plants that are closest to the pad vent. Wet walls keep the plants from needing the same amount of water and make consistent environmental conditions an uphill battle.

Fogging systems can be adjusted as needed. If a certain part of your greenhouse needs less fog due to a shadowing obstruction, or if an area needs more fog, these situations can be easily addressed and reconciled. Less than ideal environmental conditions encourage molds, mildews, pests, and diseases within your cultivation space.

Fogging systems can be adjusted as needed. If a certain part of your greenhouse needs less fog due to a shadowing obstruction, or if an area needs more fog, these situations can be easily addressed and reconciled. Less than ideal environmental conditions encourage molds, mildews, pests, and diseases within your cultivation space.